>

NEWS

December 18, 2024

October 18, 2024

August 23, 2024

July 24, 2024

May 21, 2024

April 22, 2024

April 4, 2024

January 30, 2024

December 25, 2023

December 25, 2023

November 21, 2023

November 13, 2023

February 22, 2023

February 3, 2023

January 27, 2023

December 14, 2022

December 14, 2022

January 24, 2022

May 8, 2020

November 6, 2020

January 15-17, 2020

January 16-18, 2019

January 17-19, 2018

January 18-20, 2017

October 28, 2016

October 01, 2014

September 22, 2014

>

FBC BRANDED PRODUCTS

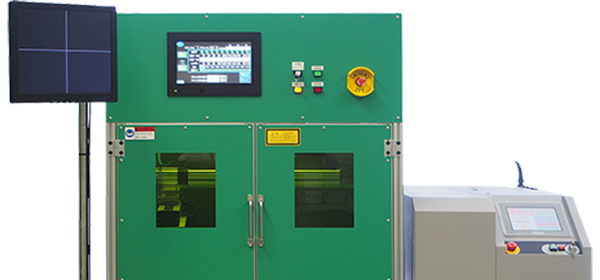

LASER WELDING EQUIPMENT

PLW Series

Welding of electronic components, electrical components, machinery components, components for medical use, optical components, precision sheet metal

Welding of battery tabs, wire materials, terminals, copper wire for motor coils, etc.

Metal welding, alloy welding, lap welding, butt welding

To Product Information page

Welding of battery tabs, wire materials, terminals, copper wire for motor coils, etc.

Metal welding, alloy welding, lap welding, butt welding

Laser Jacket Cutter

(JC Serie)

By combining together the "Laser processing conditions" and "Processing position conditions", changes in processing conditions by process and by product, and continuous processing of several locations can be performed through a simple operation of pressing the recipe selection button.

To Product Information page

Laser Shield Cutter

(SC Series)

Through optimization of the optical design, beam-shaped laser irradiation that is suitable for shield cutting is performed, and this enables high-accuracy processing and micro-processing having very less heat damage on the circumference.

To Product Information page