- HOME >

- PRODUCTS & SERVICES >

- LASER HARNESS PROCESSING MACHINES >

- Advanced Jacket Stripper

Advanced Jacket Stripper

FBC LASER HARNESS PROCESSING MACHINES

Advanced Jacket Stripper

Clamp type

Possible to strip the jacket after laser cutting

Equipped with external communication function by CC-LINK

Strips the jacket and insulation after laser processing with the laser jacket cutter (JC series) by clamping the wire with a precision motor and air cylinder.

Problems for the Jacket and Insulation strips

The ease of stripping the jacket and insulation depends on the degree of adhesion to the core and shield wires, the coating material, hardness and surface friction, outer diameter, and other condition. With general air-driven clamping strippers, it is difficult to control the clamping conditions for each wire in detail, and if the clamping pressure is increased on a wire that is difficult to strip, the frictional resistance increases and the wire cannot be stripped.

Features of the Advanced Jacket Stripper

1Strip for optimum condition for each wire

By controlling a combination of precision motors and air cylinders, stripping can be performed under optimal conditions for each wire.

2Numeric control of stripping condition and recipe management

Numerical control and recipe management of upper and lower clamp intervals and pressures are possible, so recipe registration can be done in advance for each wire. There is no downtime when changing setups if the wire to be processed changes, just select the recipe. Ideal for small-quantity, high-mix production and shared use with prototype development.

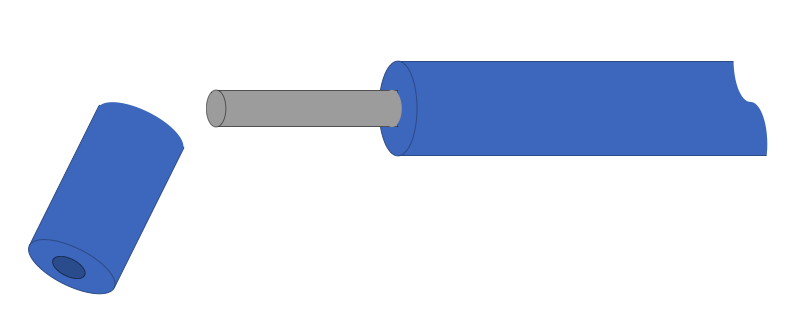

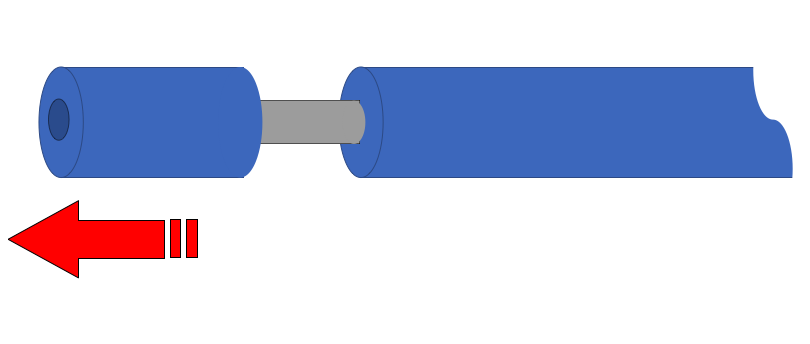

3Full stripping and half stripping are available

You can select full stripping and half stripping in the recipe.

Full stripping

Half stripping(Semi-stripping)

4Clamp head can be changeable

In the case of wires with strong adhesion to the core wire or shielded wire, or when the surface of the jacket or insulation is slippery, the rubber clamp may slip and leave residue. FBC's unique blade clamp can reliably strip the sheathing off wires that are difficult to strip. (※ Blade clamp is an option) In addition, rubber clamp and blade clamp can be easily switched without the need for tools.

5Prevent scattering of stripping debris

Equipped with a dust collector. The unique dust collection structure collects all the peeling debris after stripping. There is no need to worry about the stripper scattering inside or around the equipment or bringing it into the subsequent process. Also the unique mechanism ensures the removal of peeling debris stuck to the clamp due to static electricity, etc., so there is no peeling debris left behind that will affect the next process.

6Support the automated production line(External communication function added.)

Customer Support

We support fast operation after installation of the machine

The processing test before shipment is implemented using the customer's workpiece. The processing test data is submitted to the customer.

During installation adjustment, the processing conditions are verified through customer's workpiece, and the processing position is set.

We support changes in cable specifications and setting processing conditions for new products

We perform the processing test for new product or change of specifications and support to make recipes even after customer have purchased the machine.

We also offer development support for jigs and tools to be used and also the handling methods by exchanging information with customers.

Advanced Jacket Striper Main Specifications

| Item | AJS-100 | |||

|---|---|---|---|---|

| Stripping clamp type | Rubber clamp type (Standard) | |||

| Blade clamp type (Optional) | ||||

| Position control type and each control type | Electric position controls | Workpiece fixing clamp, Stripping clamp upper and lower, Stripping clamp unit front and back |

||

| Air drive position control | Jig positioning clamp, Processing stage front and back, Jig fixing clamp, Air blow nozzle | |||

| Supported workpiece jig | Standard jig 100mm × 100mm (Up to 130mm x 200mm is available by switching parts) |

|||

| Utility | Power supply | Main body | Single Phase 100~230V 50-60Hz Max.9A | |

| Dust collector | Single Phase 100V 50-60Hz Max.12A | |||

| Air supply | 0.5Mpa or above | |||

| Support the automated production line | Equipped with external communication function by CC-LINK | |||

AJS-100

Stripping clamp type

Blade clamp type (Optional)

Position control type and each control type

Workpiece fixing clamp, Stripping clamp upper and lower, Stripping clamp unit front and back

Air drive position control

Jig positioning clamp, Processing stage front and back, Jig fixing clamp, Air blow nozzle

Supported workpiece jig

(Up to 130mm x 200mm is available by switching parts)

Utility

Main body:Single Phase 100~230V 50-60Hz Max.9A

Dust collector:Single Phase 100V 50-60Hz Max.12A

<Air supply>

0.5Mpa or above

Support the automated production line

Demo equipment viewing

Viewing demo equipment is possible.

To request viewing, inquire through the website with the requested date, time, and number of people.

Location of demo equipment: FURUKAWA BUSSAN CO., LTD. YOKOHAMA LAB. (Iida Bldg. 1F, No.50, Tobecho 3-chome, Nishi-ku, Yokohama City, Kanagawa, Japan)

The FBC Laser Harness Processing Machine Product Lineup

We also handle pre and post process equipment. Please contact us for more information.